APL

Product Usage

Main Features

- All plastic reusable IBC for liquids.

- Rotationally moulded seamless heavy duty plastic outer frame.

- Rotationally moulded seamless heavy duty replaceable liner.

- Replaceable pallet base.

APL’s are manufactured and proven to provide users with tough long lasting materials containment and transportation capability. Easy to clean and free of potential rusting or corroding metal parts. UN performance tested and certified for the carriage of dangerous goods. The 1000L APL is UN performance tested and certified for the carriage of dangerous goods. The APL range has been in production for more than 15 years and is being successfully used in a wide range of applications.

Industry Sectors

-

Description

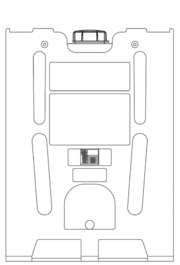

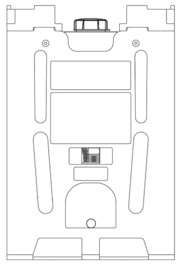

The APL is an all plastic reusable IBC. It is ideally suited for storage of corrosive liquids in hazardous applications where product integrity is a premium.

The container has a rotationally moulded HDPE¹ outer frame and LMDPE² liner. The manufacturing process produces seam free and virtually stress free thick walled containers that have excellent resistance to industrial wear and tear, corrosion and environmental stress cracking.

Side walls are provided with contents level viewing slots. The rotomoulded detachable and replaceable pallet is designed to enable units to be stacked for loading and space saving. It has four way fork lift entry with anti-tilt facility, to improve handling efficiency.

The 155mm inlet has a HDPE¹ screw cap fitted with an EPDM³ O-ring seal as standard. The outlet is a 50mm GRPP⁴ lockable ball valve which is welded to the inner receptacle spigot as standard.

The outlet is fitted throughout with EPDM³ seals and terminates in a 38mm integral camlock adapter complete with a dust cap which acts as a secondary enclosure.

DimensionsWidth/Depth (mm)1150/1150Height (mm)See product rangeInlet diameter (mm)155Outlet diameter (mm)50Tare weight (kg)See product rangeNominal capacity (L)See product rangeCompositionOuter frameHDPE¹LinerLMDPE²Pallet baseLMDPE²ClosureHDPE¹Closure gasketEPDM³OptionsViton sealsDry break valveUp to 4 top fittingsBlack linerColoured outer frameBlack topped liner for UV sensitive productsVinyl logos to reflect contents or corporate imageUN Certification1000L – Group II / SG 1.9- High Density Polyethylene

- Linear Medium Density Polythylene

- Ethylene Propylene Diene Monomer

Dimensions subject to normal manufacturing tolerances.

-

Product Range

UN 1000 (Onshore)

UN 1000 (Onshore)UN Approved

YES (CERT.FW 6011)

Capacity – L

1000

Height – mm

1605

Weight – kg

182.25

UN 1000 (Offshore)

UN 1000 (Offshore)UN Approved

YES (CERT.FW 6011)

Capacity – L

1000

Height – mm

1610

Weight – kg

182.25

1250

1250UN Approved

NO

Capacity – L

1250

Height – mm

1750

Weight – kg

182

-

Options

More details on the options outlined below can be found by clicking on the Downloads tab and selecting the pdf you require.

StandardNot AvailableOptional UN 1000 (Onshore)

UN 1000 (Onshore)UN Certified

Outer Frame CompositionHDPE¹

Liner CompositionNatural LMDPE²

Anti-static LMDPE²

Black semi-conductive LMDPE²

Closures178mm (7”) Screw cap, integral AV and PRV, Viton seal

178mm (7”) Screw cap, integral AV and PRV, EPDM3 seal

Valves50mm (2”) Ball valve with EPDM3 seal

50mm (2”) Ball valve with Viton seal

50mm (2”) Dry break valve

Top FittingsAnti-vacuum vent (AV)

Pressure relief vent (PRV)

50mm (2”) Male Cam Lock

38mm (1½”) Male Cam Lock

CustomisationColoured frame

Coloured liner

Black topped liner

UN 1000 (Offshore)

UN 1000 (Offshore)UN Certified

Outer Frame CompositionHDPE¹

Liner CompositionNatural LMDPE²

Anti-static LMDPE²

Black semi-conductive LMDPE²

Closures178mm (7”) Screw cap, integral AV and PRV, Viton seal

178mm (7”) Screw cap, integral AV and PRV, EPDM3 seal

Valves50mm (2”) Ball valve with EPDM3 seal

50mm (2”) Ball valve with Viton seal

50mm (2”) Dry break valve

Top FittingsAnti-vacuum vent (AV)

Pressure relief vent (PRV)

50mm (2”) Male Cam Lock

38mm (1½”) Male Cam Lock

CustomisationColoured frame

Coloured liner

Black topped liner

1250

1250UN Certified

Outer Frame CompositionHDPE¹

Liner CompositionNatural LMDPE²

Anti-static LMDPE²

Black semi-conductive LMDPE²

Closures178mm (7”) Screw cap, integral AV and PRV, Viton seal

178mm (7”) Screw cap, integral AV and PRV, EPDM3 seal

Valves50mm (2”) Ball valve with EPDM3 seal

50mm (2”) Ball valve with Viton seal

50mm (2”) Dry break valve

Top FittingsAnti-vacuum vent (AV)

Pressure relief vent (PRV)

50mm (2”) Male Cam Lock

38mm (1½”) Male Cam Lock

CustomisationColoured frame

Coloured liner

Black topped liner

- High Density Polyethylene

- Linear Medium Density Polythylene

- Ethylene Propylene Diene Monomer

-

Product Enquiry

Please complete the form below if you would like to enquire about our products.

Whether you’re looking for a sustainable, long-lasting alternative to single-use containers or need a custom solution for your unique business requirements, FRANCIS WARD is here to help.

Our team are ready to discuss your requirements and provide a solution that not only meets your operational needs but also supports your company’s environmental goals.