MTV

Product Usage

Main Features

Reusable IBC’s for liquids.

- Robust welded and galvanised steel frames.

- Replaceable rotationally moulded seamless plastic liner.

- Optional top inlets and bottom outlets.

- Vertical discharge design.

- Capacities from 600 – 1200 litres.

MTV’s are manufactured to provide users with tough long lasting liquids containment and transportation capabilities. Frames last many years and the liners can be replaced when necessary. Refer to our IBC Utilisation Guide to see how to maximise IBC performance and to check whether your products are compatible with our IBC’s.

MT or DG?

If you are looking for a tough long term liquids or dry goods IBC we can offer a DG range and an MT range. Which is best for your application can be discussed with our sales team. In general the MT range is preferred where compactness or height restrictions in your working environment are an issue.

Industry Sectors

-

Description

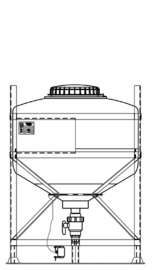

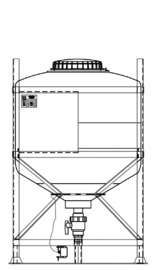

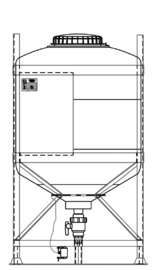

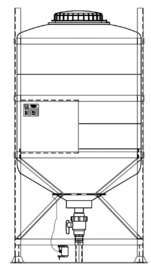

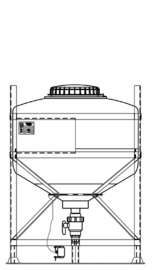

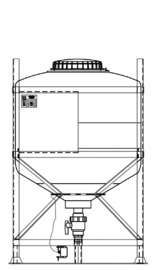

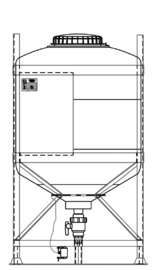

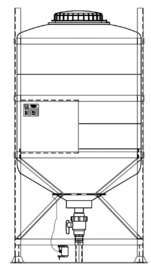

The MTV is a reusable IBC designed for the transportation and storage of viscous liquids.

The MTV liner is rotationally moulded in natural UV stabilised linear medium density polyethylene. The polymer has strong resistance to industrial wear and tear. The liner is supported and protected by a weather proof galvanised mild steel frame. The MTV is interstackable for loading and space saving and has integral four way fork truck entry with anti-tilts to improve handling efficiency.

The liner inlet which is 350mm in diameter has a PP¹ screw cap fitted with a food approved O-ring seal as standard. The standard outlet is a 50mm single union UPVC4 ball valve fitted with EPDM³ seals. It is attached to the liner via a fusion welded 50mm BSP male threaded socket.

Dimensions

Width/Depth (mm)1145/1145Height (mm)See product rangeInlet diameter (mm)350Outlet diameter (mm)50Tare weight (kg)See product rangeNominal capacity (L)See product rangeComposition

FrameGalvanised steelLinerLMDPE1ClosurePP2Closure GasketEPDM3Options

Clamp band lid, Arag lidVarious ventsColoured liner, graphics on linerAnti-tilts in frame, fork tunnels, castors- Linear Medium Density Polythylene

- Polypropylene

- Ethylene Propylene Diene Monomer

Dimensions subject to normal manufacturing tolerances.

-

Product Range

600

600Capacity – L

600

Height – mm

1470

Tare Weight

136

800

800Capacity – L

800

Height – mm

1685

Tare Weight

139

1000

1000Capacity – L

1000

Height – mm

1890

Tare Weight

147

1200

1200Capacity – L

1200

Height – mm

2120

Tare Weight

167

-

Options

More details on the options outlined below can be found by clicking on the Downloads tab and selecting the pdf you require.

StandardNot AvailableOptional 600Outer Frame Composition

600Outer Frame CompositionGalvanised Steel

Steel

Stainless Steel

Powder Coated Steel

Liner CompositionNatural LMDPE1

Anti-static LMDPE1

Black semi-conductive LMDPE1

Flame retardant LMDPE1

Closures360mm (14”) Screw cap

460mm (18”) Clamp

band lid360mm (14”) Arag lid

Valves50mm (2″) Union

ball valveTop FittingsAnti-vacuum vent (AV)

Pressure relief vent (PRV)

Combined AV and PRV

HandlingAnti-tilts in frame

Fork tunnels

Castors

CustomisationColoured liner

Graphics on liner

800Outer Frame Composition

800Outer Frame CompositionGalvanised Steel

Steel

Stainless Steel

Powder Coated Steel

Liner CompositionNatural LMDPE1

Anti-static LMDPE1

Black semi-conductive LMDPE1

Flame retardant LMDPE1

Closures360mm (14”) Screw cap

460mm (18”) Clamp

band lid360mm (14”) Arag lid

Valves50mm (2″) Union

ball valveTop FittingsAnti-vacuum vent (AV)

Pressure relief vent (PRV)

Combined AV and PRV

HandlingAnti-tilts in frame

Fork tunnels

Castors

CustomisationColoured liner

Graphics on liner

1000Outer Frame Composition

1000Outer Frame CompositionGalvanised Steel

Steel

Stainless Steel

Powder Coated Steel

Liner CompositionNatural LMDPE1

Anti-static LMDPE1

Black semi-conductive LMDPE1

Flame retardant LMDPE1

Closures360mm (14”) Screw cap

460mm (18”) Clamp

band lid360mm (14”) Arag lid

Valves50mm (2″) Union

ball valveTop FittingsAnti-vacuum vent (AV)

Pressure relief vent (PRV)

Combined AV and PRV

HandlingAnti-tilts in frame

Fork tunnels

Castors

CustomisationColoured liner

Graphics on liner

1200Outer Frame Composition

1200Outer Frame CompositionGalvanised Steel

Steel

Stainless Steel

Powder Coated Steel

Liner CompositionNatural LMDPE1

Anti-static LMDPE1

Black semi-conductive LMDPE1

Flame retardant LMDPE1

Closures360mm (14”) Screw cap

460mm (18”) Clamp

band lid360mm (14”) Arag lid

Valves50mm (2″) Union

ball valveTop FittingsAnti-vacuum vent (AV)

Pressure relief vent (PRV)

Combined AV and PRV

HandlingAnti-tilts in frame

Fork tunnels

Castors

CustomisationColoured liner

Graphics on liner

- Linear Medium Density Polythylene

-

Product Enquiry

Please complete the form below if you would like to enquire about our products.

Whether you’re looking for a sustainable, long-lasting alternative to single-use containers or need a custom solution for your unique business requirements, FRANCIS WARD is here to help.

Our team are ready to discuss your requirements and provide a solution that not only meets your operational needs but also supports your company’s environmental goals.