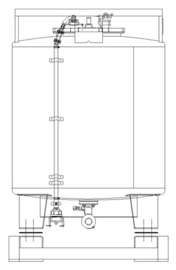

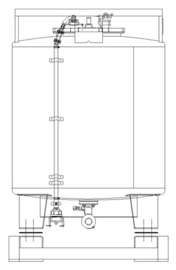

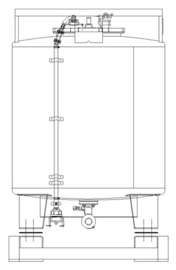

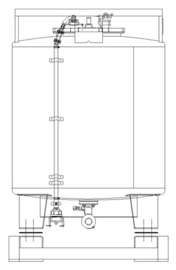

Pressure Bin 1000

Product Usage

Main Features

Reusable metallic pressure discharge IBC’s for liquids.

- Cylindrical steel tank – pressure tested to 3 Bar.

- Replaceable fork lift base.

- Tank lining options.

- Tank colour options.

- Vinyl graphics options.

All PCM IBC’s are UN performance tested and certified for the carriage of dangerous goods. PCM IBC’s are manufactured to withstand application and release of internal pressure of up to 3 BAR throughout their service life. The application of internal pressure enables the rapid discharge of container contents. Typically 1000 litres of product can be discharged in 6 minutes using an applied pressure of 2 BAR; this compares with 30 minutes to discharge using gravity alone.

The PCM 1000 is available in Stainless Steel, Mild Steel with various lining options. Our PCM’s last many years in service even with aggressive chemicals. Refer to our IBC Utilisation Guide to see how to maximise IBC performance and to check whether your products are compatible with our IBC’s.

Industry Sectors

-

Description

The PCM 1000 is a reusable IBC designed for the transportation, storage and pressure discharge of hazardous liquids.

The pressure discharge method is highly cost effective; containers are not left with customers. Instead a unit on average can achieve 3 deliveries a week. The container also comes with a “Safety Air Feed”. The SAF enables delivery personnel to discharge the IBC quickly and effectively, whilst safely standing on the ground. The cylindrical tank body, manufactured from steel, is inherently much stronger than square tanks and with no crevices it is therefore easy to clean down. The tank body is painted to provide resistance to the external environment. The pallet base is detachable and replaceable.

The pallet base connects with the tank so units can be stacked for loading and space saving. It can also be painted or galvanised to provide excellent resistance to the elements. It has four way fork truck entry with anti-tilts and a two way pallet truck entry to improve handling efficiency.

The Tank inlet which is 460mm in diameter has a HDPE¹ lid with a galvanised carrying strap and is secured by 24 bolts. It is fitted with an EPDM³ seal and 2 x 38mm camlock and dustcaps. The outlet consists of a 50mm threaded outlet pipe in HDPE from the tank body to a 50mm GRPP⁵ lockable ball valve, fitted with EPDM³ seals and terminating in a 38mm integral camlock adapter complete with a dustcap. The dustcap is retained to the valve handle via a retaining cable.

DimensionsWidth/Depth (mm)1200 / 1200 / 1810Inlet diameter (mm)460Outlet diameter (mm)50Tare weight (kg)See product rangeNominal capacity (L)1000CompositionTankSteelLiningLLDPE¹Pallet baseSteelClosureHDPE¹Closure gasketEPDM³OptionsVarious top vents and portsStainless steel constructionPainted tank and pallet baseHypalon rubber tank liningVinyls on tankLabel plates on tankOutlet valve seal optionsUN CertificationGP II, SG 2.6- High Density Polyethylene

- Linear Medium Density Polythylene

- Ethylene Propylene Diene Monomer

Dimensions subject to normal manufacturing tolerances.

-

Product Range

1000 MS PE Lined

1000 MS PE LinedCapacity – L

1000

Height – mm

1810

Weight – kg

323

1000 MS Rubber Lined

1000 MS Rubber LinedCapacity – L

1000

Height – mm

1810

Weight – kg

323

1000 SS

1000 SSCapacity – L

1000

Height – mm

1810

Weight – kg

292

-

Options

More details on the options outlined below can be found by clicking on the Downloads tab and selecting the pdf you require.

StandardNot AvailableOptional 1000 MS PE Lined

1000 MS PE LinedUN Certified

Tank CompositionPainted Steel

Stainless SteelTank Lining CompositionNatural LLDPE¹

Rubber (Hypalon)

Unlined

Closures300mm (12”) 12 bolt lid – SS2

516mm (20”) 24 bolt lid – SS2

516mm (20”) 24 bolt lid – HDPE3

Valves50mm (2”) GRPP4 Ball valve

with EPDM5 seal50mm (2”) GRPP4 Ball valve

with Viton seal50mm (2”) SS2 Ball valve

with EPDM5 seal50mm (2”) SS2 Ball valve

with Viton sealTop Fittings38mm (1½”) GRPP4 Cam Lock

and dust cap50mm (2”) GRPP4 Cam Lock

and dust cap75mm (3”) GRPP4 Cam Lock

and dust cap38mm (1½”) SS2 Cam Lock

and dust cap50mm (2”) SS2 Cam Lock

and dust cap75mm (3”) SS2 Cam Lock

and dust cap25mm (1”) SS2 Pressure relief vent (PRV)

50mm (2”) GRPP4 Combined

anti-vacuum and PRVCustomisationTank colour choice

Pallet base paint choice

Galvanised pallet base

SS2 Label plates

Vinyls, corporate and/or contents

Pallet base drip guard

- Linear Low Density Polyethylene

- Stainless Steel

- High Density Polyethylene

- Glass Reinforced Polypropylene

- Ethylene Propylene Diene Monomer

-

Product Enquiry

Please complete the form below if you would like to enquire about our products.

Whether you’re looking for a sustainable, long-lasting alternative to single-use containers or need a custom solution for your unique business requirements, FRANCIS WARD is here to help.

Our team are ready to discuss your requirements and provide a solution that not only meets your operational needs but also supports your company’s environmental goals.